The differences between corona rings and grading rings are extremely subtle when viewing from the back.

Both rings are made of aluminum alloy or hot dip galvanized steel.

The corona rings are used in high voltage test equipment and power systems, which is mainly made of aluminum alloy.

A grading ring, it is similar with corona ring, which is also used on high voltage equipment. But they encircle insulators rather than conductors.

Corona rings and grading rings are common parts in power transmission line and high voltage industry. They are easy to operate, convenient to move, and fast to install.

Today we’re going to go over 6 differences between corona rings and grading rings. This should help all you newbies out there who don’t know the difference. So let’s get into it, shall we?

If you’ve ever wondered about the differences between grading rings and corona rings for high voltage industry, read this guide.

1.Definition Differences Between Corona Rings And Grading Rings

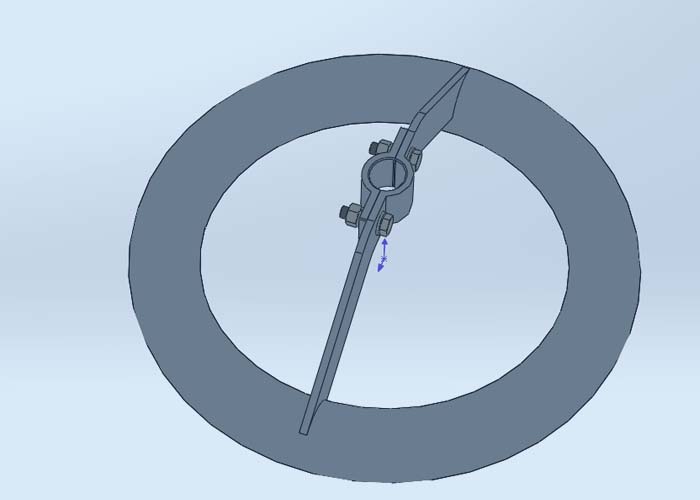

Corona rings are toroidal shaped aluminum or steel rings which are installed at the end of power trasnformer bushings and high vlotage insulators strings.

They are also known as anti corona rings. Corona rings are used to prevent corona discharge that occurs in HV transmission lines.

Corona discharge or corona loss is a fundamental issue with super high voltage power lines which causes power loss. One way to reduce corona discharge is using suitable dimenisons corona rings.

The systems of extra/ultra high voltage (EHV/UHV) transmission lines and substations can produce sharp corona.

The main difference between extra and ultra high voltage is the voltage level.

According to IEEE 1312:

- Extra-High Voltage (EHV) – ( ≥345 kV & ≤765 kV )

- Ultra-High Voltage (UHV) – ( >765 kV & ≤1100 kV )

Surely the UHV lines are made for very long distances because the voltage is very high and losses will be less. However EHV for lower distances than UHV.

UHV’s initial cost and equipment size will be surely higher than in EHV. But as said that UHV line will be very efficient for long distances and very high powers than EHV.

To limit the consequent radio interference and audible noise on these systems, suitable aluminum corona rings are manufactured and applied.

The shapes of corona rings could vary from circular to rectangular with smooth bends of piping.

Many China manufacturers seem to adopt trial and error method for arriving at the final design of these rings.

As such neither the present testing standard nor the final design adopted consider the practical scenario like corona produced by deposition of dirt, bird droppings, etc.

The present work aims to make the first step in addressing this practically important problem. This requires an accurate evaluation of the electric field and a reliable method for the evaluation of corona inception.

What Are Corona Rings?

The corona rings are one of the most important parts of the high voltage testing equipment, and it’s also the first choice for many HV engineers, products managers and end users.

For the corona ring, it is an ideal choice for corona treatment.

Generally the corona ring needs to be polished bright to achieve more smooth and no burr surface finish to ensure better corona control effect.

The aluminum corona rings are made of pure aluminum and alloy, with a surface treated by polishing or anodic oxidation, which makes it have a good surface hardness, dielectric strength and impact resistance. It also has a good insulation and can be easily repaired by grinding.

Corona discharge occurs when the electric field (potential gradient) at the surface of conductors exceed a critical value, called as critical disruptive voltage.

The value of critical disruptive voltage varies with atmospheric condition. Its value is roughly 30 kV/cm. The electric field greatest where the curvature is sharpest.

Therefore, corona discharge occurs first at the points where the curvature is greatest – i.e. at suspension points, corners and edges.

Corona rings are installed at these points to prevent corona formation.

Corona is a plasma discharge, which occurs when the electric field around a conductor exceeds the dielectric strength of the air, causing electrical current to flow through the air. Corona discharges are typically seen as a faint bluish glow caused by ionization of the surrounding gas.

The ionization can be further enhanced if impurities (e.g., dust or smoke particles) are present in the air. The resulting partial discharge can produce ozone and other harmful products.

The common spark plug uses corona discharge to ignite the air-fuel mixture in internal combustion engines. Corona discharges can also occur on high voltage power lines and other large electrical equipment such as transformers, bushing, and insulators.

Corona rings are used for improving and stabilizing corona discharge. Corona rings are used on transformers and insulators to help stabilize the corona discharge from occurring at random along an insulated conductor or surface.

Corona rings are typically made from copper or aluminum with a very small gap between it and the conductor that it surrounds. This gap helps prevent arcing across the gap to ground when there is no voltage applied to the conductor that it surrounds but may not prevent arcing between it and that conductor when voltage is applied, thus creating corona discharge.

What Are Grading Rings?

A grading ring, it is similar with corona ring, which is also used on high voltage equipment. But they encircle insulators rather than conductors.

Although they may also serve to suppress corona, grading rings main purpose is to reduce the potential gradient along the insulator, preventing premature electrical breakdown.

The grading ring is widely used for insulators industries.

The grading ring surrounds the end of the insulator next to the high voltage conductor.

It reduces the gradient at the end, resulting in a more even voltage gradient along the insulator, allowing a shorter, cheaper insulator to be used for a given voltage.

Grading rings also reduce aging and deterioration of the insulator that can occur at the high voltage end due to the high electric field there.

Grading rings are used on porcelain insulators to keep the electrical field off the porcelain body of the insulator and thus prevent flashover.

The grading rings are placed at a suitable distance from each other on a post insulator or at suitable intervals on a suspension insulator string so as to cover the whole length of porcelain body above the shed.

In post insulators these rings are generally metallic but in suspension type they are made of porcelain.

2.Function Differences Between Corona Rings And Grading Rings

The corona ring is intended to electrically shield the bushing terminal and connections.

At sharp point (like bushing head) the electric field is high which results in corona.

Aluminum corona ring (corona shielding ring) should be installed at this point.

The ring is suitable for the voltage form of alternating current (AC), which can distribute the high voltage evenly around the object to ensure that there is no potential difference (PD) between the various parts of the ring.

The larger outside diameter, smooth polishing surface finish of aluminum corona rings can help control the local electric field.

So electric field gradient reduces and suppresses the corona. As the testing voltage increases the outside diameter of the required corona ring/shielding ring must also increase to obtain better corona control effect.

The customized aluminum corona rings are usually made from 6061 thin wall tubing or pipe that is formed and welded with appropriate supporting brackets and other mounting standards.

Most equipment manufacturer provide corona rings base on testing such gas insulated switchgear, voltage divider, high voltage bushing, impulse voltage generator system, current generator testing system, etc.

A grading ring, it is similar with corona ring, which is also used on high voltage equipment. But they encircle insulators rather than conductors.

Although they may also serve to suppress corona, grading rings main purpose is to reduce the potential gradient along the insulator, preventing premature electrical breakdown.

Die casting type grading rings are usually made of A380 or ZL101 material, sand and permanent mold A356.

For high voltage insulators, some manufacturers recommend one piece grading ring and for 500 kV grade and above two rings. However, for composite insulator application, the grading ring is recommended for 220/230 kV.

3.Production Process Differences Between Corona Rings And Grading Rings

How To Make One Piece Corona Ring?

Corona rings are widely used in high voltage industry.

Today we will introduce you to the high quality corona rings production process.

There are nine key points for the production process of corona rings:

- Corona Rings Drawing Analysis

- Corona Rings Mould And Raw Materials Preparation

- CNC Machining And Pipe Bending

- Corona Rings Sheet Metal And Fabrication Process

- Corona Rings Welding Process

- Polishing And Cleaning Process of Corona Rings

- Corona Rings Surface Treatment

- Corona Rings Inspection And Packaging Before Shipment

- Corona Rings Warranty Policy

How To Make One Piece Grading Ring?

At first, you should know what the material is available and which is grading ring application.

Here in China, there are two main production process categories of grading rings.

One method is called pipe bending, another one is called pressure die casting.

According to real production process, the right aluminum material will be used for them.

Die casting type grading rings are usually made of A380 or ZL101 material, sand and permanent mold A356.

Aluminum 6061, 6063 and 3A21 grade are popular for pipe bending grading ring production.

4.Raw Materials Differences Between Corona Rings And Grading Rings

What Are The Materials Of Corona Rings?

What are the materials of corona rings? It depends on corona rings design and manufacturing process.

The custom aluminum corona rings are usually made from 6061 thin wall tubing or pipe that is formed and welded; with appropriate supporting brackets and other mounting standards.

In some conditions, the stainless steel materials will be used.

Aluminium Alloy:

Aluminum alloy is a popular metal material to use for corona rings production.

Because it is both cost effective and high weather resistance.

The soft hardness is easily processing and polishing.

Die casting rings materials are usually A380 and ZL101.

ZL101 die casting aluminum alloy can be strengthened by heat treatment, which has natural aging ability, high strength and good plasticity.

ZL101 die casting aluminum alloy has excellent casting properties, good fluidity, small linear shrinkage, low thermal cracking tendency and high air tightness. But it has a slight tendency to produce porosity and shrinkage.

This alloy has high corrosion resistance, good weldability and general machinability.

A380 type die casting aluminum alloy is the most common special aluminum alloy because it integrates the characteristics of easy casting, easy machining, and good heat conduction.

It has strong mobility, pressure bearing, and high temperature resistance.

Although the A380 type alloy has always been considered convenient for machining, it is slightly rough due to its higher silicon content.

It is widely used in various products, including chassis of electrical equipment, engine brackets, gearboxes, furniture, generators and hand tools, etc.

Of course, it is also the material of the aluminum die casting corona ring.

Stainless Steel:

Stainless steel is the kind of material which is not easy rust, acid resistance and corrosion resistance, so it is widely used in light industry and heavy industry.

Sometimes end users need some special corona rings made of stainless steel for outdoor applications.

Grade 201 reduces corona rings producing cost, increases mechanical strength and makes grade 201 work harden at a faster rate than grade 304 stainless steel material.

Grade 304 stainless steel material is a smart choice for your stainless steel corona rings project and longevity. It is cost-effective in comparison to other stainless steel materials.

Grade 304 material’s high quality and durability ensures that your product lasts a long time and the production of it is suitable for almost industry use.

Grade 316 stainless steel material, is a popular grade of stainless steel where superior corrosion resistance is of primary importance.

Grade 316 stainless steel corna ring is used for outdoor high voltage applications.

What Are The Materials Of Grading Rings?

With the development of technology, aluminum alloy for grading ring production has become the current trend.

The use of aluminum alloys to make these rings has the following advantages:

- The overall weight of the ring is reduced, which is suitable for insulator installation

- Aluminum alloy also has the hardness and strength of some metal, which meets the safety standards of manufacturing

- Compared with normal steel, aluminum alloy has stronger oxidation resistance

- The metallic luster of aluminum alloy is better than steel, which is more in line with the appearance of grading ring

- Compared with the price of stainless steel, the price of aluminum alloy is more affordable and is the choice of China grading ring manufacturers

5.Applications Differences Between Corona Rings And Grading Rings

Corona Rings Applications

The larger outside diameter, smooth polishing surface finish of aluminum corona rings and corona shielding rings can help control the local electric field.

So electric field gradient reduces and suppresses the corona.

As the testing voltage increases the outside diameter of the required corona ring and corona shielding ring must also increase to obtain better corona control effect.

- Aluminum Corona Rings For Power Transformers

- Aluminum Corona Rings For High Voltage Bushings

- Aluminum Corona Rings For High Voltage Laboratory

- Aluminum Corona Rings For Gas Insulated Switchgear (GIS)

- Aluminum Corona Rings For UHVDC Converter Valves

- Aluminum Corona Rings For High Voltage Capacitors

- Aluminum Corona Rings For Power Cables

Grading Rings Applications

HIGHV custom made grading rings are widely used for below different fields:

- Insulator

- Surge and lightning arrester

- Current transformer

- High voltage test equipment

- Power transmission and transformation line

6.Design Process Differences Between Corona Rings And Grading Rings

Design Process In Corona Rings

If designing the corona rings for power transformer’s bushings or UHV systems still seems overly complex, the best thing to do is consult an design and manufacturing expert.

The main design process of corona rings can be divided into seven stages:

- New Mould Design

- Choosing The Right Raw Materials For Corona Ring Design

- Aluminum Corona Ring Wall Thickness Design

- Aluminum Corona Ring Outer Diameter Design

- Installation Distance And Dimensions Design

- Brackets And Mounting Plate Design

- Choosing The Right Design Expert

Design Process In Grading Rings

When design grading rings with Chinese manufacturers, if you are worried about the results of products design. If yes, here is the right place you come to visit.

The main design process of grading rings can be divided into six stages:

- Aluminum Grading Ring New Mould Design

- Choosing The Right Raw Materials For Aluminum Grading Ring Design

- Aluminum Grading Ring Wall Thickness Design

- Aluminum Grading Ring Outer Diameter Design

- Installation Distance And Dimensions Design

- Brackets And Clamps Design

Conclusion

Corona rings and grading rings can be easily confused, but there are 6 major differences between these two components that we should take note of.

Highv is one of the professional aluminum corona rings and grading rings manufacturers in China.

When it comes to corona rings and grading rings design, production and complete solutions, Highv’s 30 years of manufacturing experience will really show.

Feel free to inquiry us about your corona rings and grading rings projects.