WORLD'S LEADING CORONA RINGS MANUFACTURERS AND SUPPLIERS

Corona Rings And Grading Rings Manufacturing Expert

Highv is one of the professional corona rings manufacturers in China, we are top leader aluminum corona rings factory, corona shielding rings and grading rings suppliers.

24/7 Hours Services

580+ Happy Customers

30000+ Projects Delivered

ISO 9001 Certified

What Corona Rings And Shielding Products We Have

Masters In Corona Rings And Shielding Components Manufacturing

Highv is a professional manufacturing expert since 1993, we are top leader Chinese aluminum corona rings factory, corona shielding solutions supplier, aluminum corona shielding rings and grading rings manufacturer.

We continue to supply corona shielding control products, including aluminum corona rings, grading rings, aluminum corona shielding rings, aluminum corona shields to hundreds of industries for:

• Power transformer, voltage transformer and current transformer

• GIS (gas insulated switchgear)

• High voltage laboratory (high voltage test equipment)

• Impulse voltage generator system

• Current generator testing system

• Substation and high voltage transmission line

• Surge arrester and lightning arrester

• High voltage capacitor banks and dividers

• High voltage bushing

• Insulator

And so much more! From aluminum pipe and plate materials to aluminum corona rings, here we can help you all corona shielding solutions.

What We Do

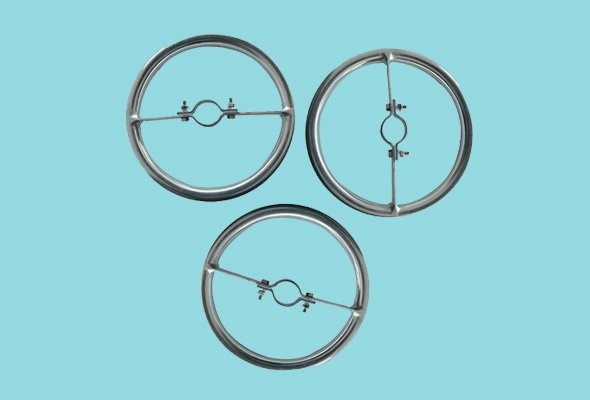

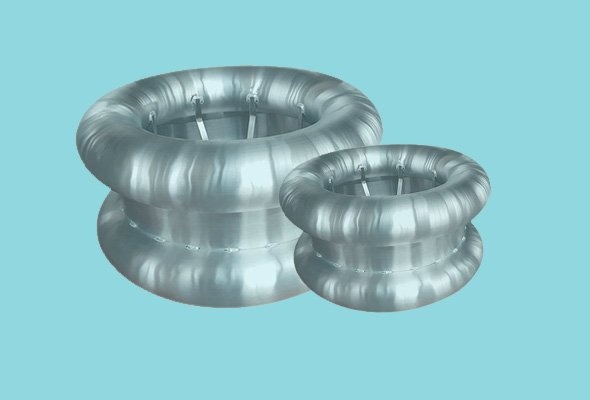

Corona Rings

Corona rings are mainly made of aluminum alloy, which are widely used in high voltage test equipment and power systems. Such as high voltage laboratory, substation, high voltage transmission line, AC voltage system, etc.

Aluminum corona rings polishing bright surface can ensure better corona control effect.

Grading Rings

Grading rings can be divided as die casting type and pipe bending ones, which is suitable for insulator, surge arrester, current transformer, power transmission and transformation line, etc.

Grading ring’s main purpose is to reduce the potential gradient along the insulator, preventing premature electrical breakdown.

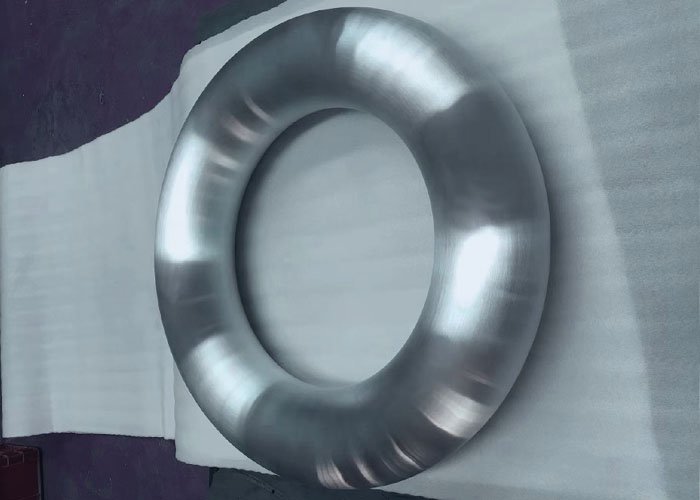

Corona Shielding Rings

Aluminum corona shielding rings, they are also known as aluminum electrodes.

According to the design drawing and requirements, Highv professional team will help you confirm the best aluminum corona shielding ring solutions for every high voltage project.

It is designed for high voltage test purpose, to ensure better corona shielding effect.

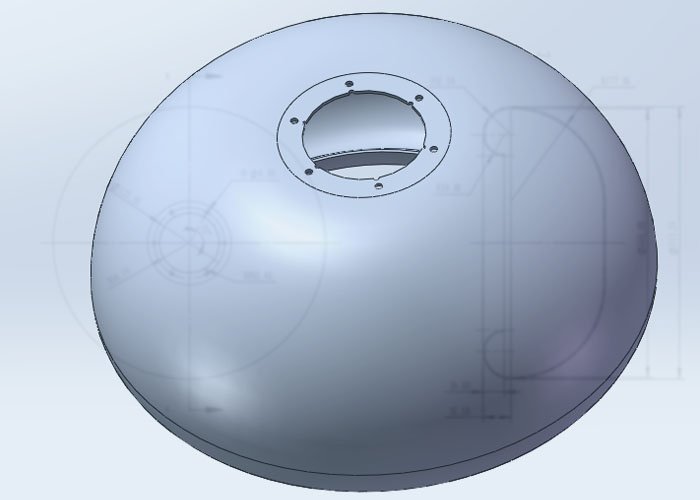

Corona Shielding Covers

Product Name: Corona Shielding Cover

Raw Material: Aluminum/Copper

Size: Customized

Corona Shielding Spheres

Corona shielding sphere is also called corona shielding ball.

It is designed for high voltage test purpose.

Aluminum Fabrication

Highv, Management with western-think, is capable of supplying world class standards when it comes to aluminum fabrication.

Aluminum Corona Rings

Aluminum corona rings, also called aluminum anti corona rings, they are the toroids of conductive materials, usually aluminum alloy, which are attached to a terminal of high voltage equipments.

Aluminum Anti Corona Rings

The role of the aluminum anti corona rings are to distribute the electric field gradient and lower its maximum values below the corona threshold, preventing corona discharge.

Aluminum Corona Shields

When it comes to aluminum corona shields production, we get that you need long term partners, not just suppliers. HIGHV offers aluminum corona shields with a fast and efficient method for global users.

Industries We Serve!

Need Help With Easier Corona Rings And Corona Shielding Solutions?

We Are Experts!

6 Key Reasons Why Fortune500 Companies Choose Us

Over 28 Years Design & Manufacturing Experience

Having carried out precision and rapid manufacturing for over 28 years, our expert team have built up rich experience. We can handle all types of high voltage corona rings and shielding parts projects. Check Case Study

One Stop Corona Rings And Shielding Solutions

We offer metal raw materials analysis, corona rings and shields products designing, sampling, manufacturing, QA, logistic, Keep advising not just manufacturing. Check All Corona Shielding Solutions

High Quality

HIGHV QC department specializing in quality control to guarantee the quality of each custom made corona shield product. Check Our Quality Management

Competitive Price

Buying directly from HIGHV factories, saving at least 30%-40% from buy in Europe&USA markets. Get Your Instant Quote Today

24/7 Online Support & Free Quote

A complete set of customer management system support.

24/7 service, also easily face to face meeting, fast feedback.

Continuous Development

We offer continuous products development and support, keep update your new idea, commit an upgrade service.

The only place where you’ll get the perfect corona shielding solutions for all your high volatge industry needs.

Testimonials

Your Review Is Important for Us!

Please kindly send your testimonial to Highv team.

See Our Partners

Develop Your Custom Corona Rings And Shielding Components

If you have any new designs, you can send us detailed 2D & 3D drawings or samples. Our team of expert is here for you. Ask one of our design, engineering, and manufacturing experts your corona rings and shielding parts related questions.

Already have one corona ring in your mind with adjustments that are ready for production? Let us guide you through customizing corona rings we already produce. Get your instant quote to start your customization journey.

Blog & News

Get All Resources About Custom Corona Rings & Shielding Components

Blog | March 15, 2021

Blog | January 27, 2021

When it comes to aluminum corona rings production, Highv’s 30 years of manufacturing experience really shows. Let’s introduce how to make aluminum corona ring here.

Blog | March 7, 2021

When deal international business with Chinese factories, if you are worried about the quality of aluminum corona rings and shields packaging. Here is the right place you come to visit.

Blog | March 13, 2021

Corona rings and shield parts surface treatment is one of the major factors that every buyer should consider when purchasing them from China market.

Commonly Asked Questions

- The easiest way to find your aluminum corona rings manufacturers in China is by searching “ aluminum corona rings manufacturers China” in google.

- Your corona ring supplier should provide you the best solution as soon as possible.

- Your aluminum corona rings manufacturers should provide competitive price and good service to support your high voltage projects.

If the mould is ready on stock, the MOQ will be less. 1 piece corona ring is workable.

If you need customized ones, the trial order MOQ is will be negotiated.

It depends on your aluminum corona rings order total quantity.

Usually from the start of the order to the completion of production for about 2-3 weeks.

For 24/7 monitored technical support on products and corona shielding solutions

Email us or call us any time, any day.

We’ll have your problem fixed in short time.

The first and most important among our pre-sales support is, at every stage, providing comprehensive information for you, communicating with you to determine your unique products needs, finally helping you to make the most reasonable purchasing decisions.

For example, when you want to purchase aluminum corona rings from Highv, the following information should be clarified before order:

- Detailed Drawings (CAD/PRO-E/UG/SOLIDWORS software support)

- Application (High Voltage Bushing, Power Transformer, etc.)

- Material Grade (Aluminum Alloy, Stainless Steel, Copper, etc.)

- Dimensions (Tube Wall Thickness, Outer Diameter, Others)

- Surface Treatment (Polishing Bright, Blue Color Painting, Galvanized, Coating Insulating Varnish, Anodic Oxidation, etc.)

- Production Type of Corona Ring (Pipe Bending or Pressure Die Casting)

- Voltage Class (170kV, 230kV, 500kV, 800kV, 1100kV, etc.)

- Packaging Type (Carton Box, Wooden Pallet, Wooden Case)

- Delivery Time (15-20 Working days After Confirmed The Deposit)

- Quoted Term (EXW, FCA, FOB, CFR, CIF, DDP, etc.)

If you want to buy other products from us or require service support, please don’t hesitate to contact us at any time.

The spirit of our company is that safety is the foundation of production and quality makes customers. We pay more attention to quality support, supply scope, inspection, testing standard, shipment packing, after-sales service.

We have passed ISO9001 quality management system certification.

Quality Control Process:

1) Checking the metal raw material after they reach our factory- Incoming quality control

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production-In process quality control

4) Checking the goods after they are produced- Final quality control

5) Checking the goods before shipment

At the same time, we will help take photos and shoot videos for you if you need. Every corona ring and shielding product will be fully assembled and carefully tested before packing and shipping.

Read More

What Are Aluminum Corona Rings?

The aluminum corona rings are one of the most important parts of the high voltage testing equipment, and it’s also the first choice for many HV engineers, products managers and end users.

For the aluminum corona ring, it is an ideal choice for corona treatment.

Generally the aluminum corona ring needs to be polished bright to achieve more smooth and no burr surface finish to ensure better corona control effect.

The aluminum corona rings are made of pure aluminum and alloy, with a surface treated by polishing or anodic oxidation, which makes it have a good surface hardness, dielectric strength and impact resistance. It also has a good insulation and can be easily repaired by grinding.

What Are Corona Rings Used For?

A corona ring is a circular ring of metal or other material that is placed close to the end of an electrical conductor where it is connected to another conductor.

Corona rings are used in high voltage applications such as transformers and power transmission lines, where the electric fields are high enough that the ionisation of air around a conductor may occur, causing loss of energy from the system (the so-called “corona effect”). The corona ring confines this ionisation within a small area, reducing the energy lost.

- Corona Rings For Power Transformers

- Corona Rings For High Voltage Bushings

- Corona Rings For High Voltage Laboratory

- Corona Rings For Gas Insulated Switchgear (GIS)

- Corona Rings For UHVDC Converter Valves

- Corona Rings For High Voltage Capacitors

- Corona Rings For Power Cables

What Are The Types Of Corona Rings?

Types of corona rings include:

- Single and double corona rings

- High voltage test use corona rings

- Aluminum and stainless steel corona rings

- Insulating corona rings

What Are The Features Of Corona Rings?

- High strength

- Excellent polishing bright finish

- Corona shielding advantage

- High moistureproof

- Tasteless and non-poisonous

- Anti-corona and Anti-causticity

- Competitive price with good quality

- Low MOQ (1 piece/set is even acceptable in some special conditions)

- Customized sizes and specifications /OEM is also available

What Is The Purpose Of A Corona Ring?

A corona ring is an electrical device used to minimize the corona effect, which is due to high voltage and low current.

Corona rings are designed for transformers or power lines that operate at high voltages.

Corona rings are used essentially in high-voltage AC transmission lines and substations, where they are installed near the conductors in order to mitigate the negative effects of the coronal discharge.

The corona ring provides an alternative path for the electrons to move, preventing them from arcing between lines. This reduces noise, improves power quality and increases power factor. This can also extend the life of the transmission line by reducing ionized air particles that can damage insulation.

How Does The Aluminum Corona Rings Work?

Corona rings are used to increase the voltage across a component or surface. Corona rings are generally made of aluminum and used in overhead power lines to increase the surface potential and reduce corona loss. These rings are mounted on crossarms.

Corona is an ionized gas occurring naturally in the environment, which can also be produced artificially by high-voltage electrical discharges.

Corona is generally unwanted, especially in electricity transmission where it wastes energy, increases conductor corona loss and radio interference, and can cause damage to insulators. Corona discharge from conductors may also produce ozone (O3) as a pollutant and can cause noise or audible sound.

High voltage corona discharges occur around most high voltage equipment such as power lines and transformers; the electric field strength required for corona depends on air density, moisture content, presence of contaminants or dust, insulation type, shape of the conductor, etc., but is typically 30–40 kV/cm for dry air at sea level pressure (atm).

At lower voltages the air is normally an insulator; however, as voltage increases a stage is reached where small areas of ionization occur and current flows through these paths creating characteristic “streamer” discharges.

What Are The Benefits Of Using Aluminum Corona Rings?

Aluminum corona rings are used in high voltage testing equipment, such as power transformers, HV bushings, power cables.

The benefits of using aluminum corona rings are:

- High reliability: The aluminum corona ring manufactured by us has high quality that provides good corona control effect, which allows the device to work under high voltage smoothly.

- Easy installation: The installed corona rings are ready for immediate use, which ensures a short downtime of your test during maintenance.

- Affordable price: We can offer you an aluminum corona ring at an affordable price due to our extensive experience in manufacturing this type of products and close cooperation with suppliers of aluminum, copper and stainless steel raw materials.

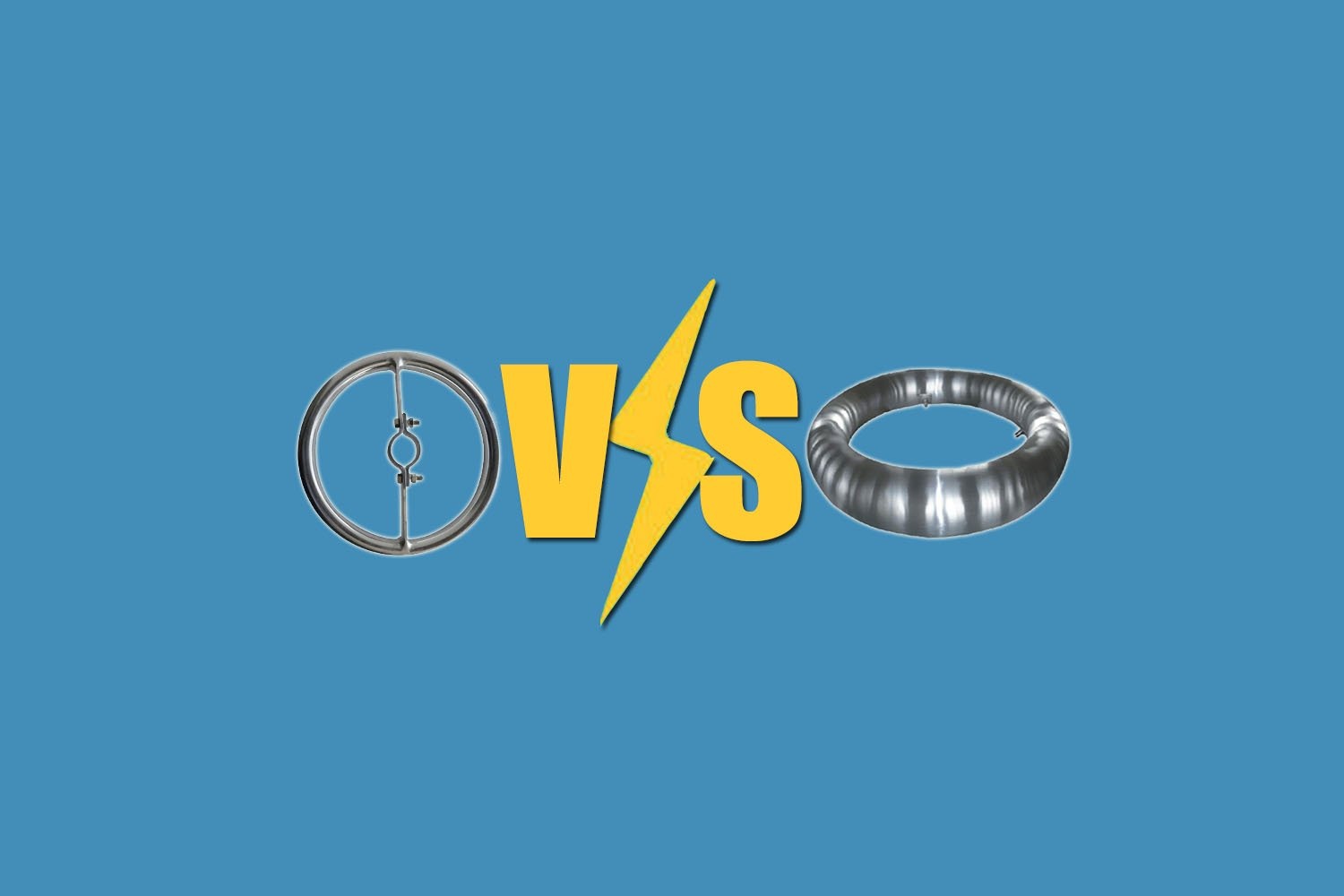

Difference Between Corona Ring And Grading Ring

The corona ring is used in high voltage test equipment and power systems, which is mainly made of aluminum alloy.

A grading ring, it is similar with corona ring, which is also used on high voltage equipment. But they encircle insulators rather than conductors.

Corona rings and grading rings are common parts in power transmission line and high voltage industry.

They are easy to operate, convenient to move, and fast to install.

Do you want to know difference between corona rings and grading rings?

Corona ring:

A corona ring is a ring which is positioned at the top of an bushing or insulator. It is used to increase the effective creepage distance by reducing the voltage gradient near the insulator surface.

The corona ring may be either solid or tubular and is usually made of aluminum, stainless steel or other metal having low resistivity and high resistivity to weathering.

Grading rings:

Grading rings are used on porcelain insulators to keep the electrical field off the porcelain body of the insulator and thus prevent flashover.

The grading rings are placed at a suitable distance from each other on a post insulator or at suitable intervals on a suspension insulator string so as to cover the whole length of porcelain body above the shed.

In post insulators these rings are generally metallic but in suspension type they are made of porcelain.

What Is Corona Discharge On A Corona Ring?

Corona is a plasma discharge, which occurs when the electric field around a conductor exceeds the dielectric strength of the air, causing electrical current to flow through the air. Corona discharges are typically seen as a faint bluish glow caused by ionization of the surrounding gas.

The ionization can be further enhanced if impurities (e.g., dust or smoke particles) are present in the air. The resulting partial discharge can produce ozone and other harmful products.

The common spark plug uses corona discharge to ignite the air-fuel mixture in internal combustion engines. Corona discharges can also occur on high voltage power lines and other large electrical equipment such as transformers, bushing, and insulators.

Corona rings are used for improving and stabilizing corona discharge. Corona rings are used on transformers and insulators to help stabilize the corona discharge from occurring at random along an insulated conductor or surface.

Corona rings are typically made from copper or aluminum with a very small gap between it and the conductor that it surrounds. This gap helps prevent arcing across the gap to ground when there is no voltage applied to the conductor that it surrounds but may not prevent arcing between it and that conductor when voltage is applied, thus creating corona discharge.

What Are Grading Rings?

A grading ring, it is similar with corona ring, which is also used on high voltage equipment. But they encircle insulators rather than conductors.

Although they may also serve to suppress corona, grading rings main purpose is to reduce the potential gradient along the insulator, preventing premature electrical breakdown.

The grading ring is widely used for insulators industries.

The grading ring surrounds the end of the insulator next to the high voltage conductor.

It reduces the gradient at the end, resulting in a more even voltage gradient along the insulator, allowing a shorter, cheaper insulator to be used for a given voltage.

Grading rings also reduce aging and deterioration of the insulator that can occur at the high voltage end due to the high electric field there.

What Are Corona Shielding Rings?

Corona shielding rings are hollow round pipe material, which are wrapped around the conductor to reduce corona.

Corona shielding ring, it is also known as corona ring or electrode.

Types of corona shielding rings:

- Metal corona shielding ring: It is a round hollow pipe of the metal. Mostly aluminum is used. Its thickness depends upon the high voltage level. At EHV level, its thickness is 1.5 mm and at UHV level, it is 3 mm thick.

- Non-metal corona shielding ring: These rings are made up of polymeric material and are used for high voltage power transmission lines. They have a low dielectric constant and less weight as compared to metal corona shielding rings.

What Are High Voltage Corona Rings?

High voltage corona rings, also named aluminum shielding rings, are used for high voltage test equipment.

High voltage corona rings are made by pipe bending or die casting.

What Are Aluminum Corona Shields?

The aluminum corona shields are used in high voltage bushing and power testing equipment, which are mainly made of aluminum alloy.

Generally the corona shield needs to be polished bright to achieve more smooth and no burr surface finish to ensure better corona shielding effect.

Corona shielding cover is widely used on the end fittings of high voltage bushings and other high voltage testing equipments. High voltage can result in unwanted noise and corona, so corona shielding covers are needed.

Corona shielding cover is suitable for the voltage form of alternating current (AC), which can distribute the high voltage evenly around the object to ensure that there is no potential difference (PD) between the various parts of the cover.

Why Corona Ring In Substation?

Corona rings are used to reduce corona effect.

Corona rings are installed in substation.

In power transmission high voltage lines and substations, corona discharge is a major problem, which causes voltage loss, energy losses, high noise level, radio interference and damage of insulation.

If the free electrons and ions concentration is high in air then this causes the formation of corona. The charge carriers are created by ionization process by Corona effect.

In power system, Corona phenomenon leads to Carbon deposition on insulator string and surface erosion of conductor material. Thus it is important to reduce the corona due to Corona effect.

Corona rings are installed at both ends of conductor terminals in substation to minimize the corona effect.

Why Corona Ring In Transmission Line?

Corona rings are used in high voltage transmission lines.

The main purpose of corona ring is to reduce the corona loss.

When a high voltage is applied to the conductor, it produces electro-static field around it which causes corona effect. To reduce this effect and loss, we use corona rings.

Corona rings are used in transmission lines and power cables having 11kV and above rated voltages.

Why Corona Ring In Insulator?

Corona discharge is a phenomenon that occurs when the voltage difference between two electrodes exceeds a certain value (the breakdown voltage). Corona discharge is expressed as a luminous discharge of air around the electrode. Corona is also expressed in terms of sound and heat. The corona discharge phenomenon discharges the electricity through the air, which can cause a fire. Corona discharge will be generated around an insulator or conductor when it is charged with high voltage. Corona discharge can be divided into surface corona and internal corona according to its location.

The reason why corona rings are used for high voltage insulators:

1.”corona ring” is generally used to prevent over-voltage damage of high-voltage wire or busbar equipment, so high-power equipment must use “corona ring”.

2.In the case of outdoor high-voltage insulators, because of its own structure, it will cause partial pressure concentration at the root of the insulator, resulting in excessive pressure during operation, which may cause flashover on the insulation surface. In order to reduce this pressure concentration, we need to design a suitable shape and size. Corona ring provides enough space for stress distribution and prevents flashover at a certain distance from the ground wire end.

What Is Anti Corona Ring?

Aluminum anti corona rings, also called aluminum corona control rings, they are the toroids of conductive materials, usually aluminum alloy, which are attached to a terminal of high voltage equipments.

The role of the aluminum anti corona rings are to distribute the electric field gradient and lower its maximum values below the corona threshold, preventing corona discharge.

Aluminum anti corona rings are used on very high voltage power transmission insulators and switchgears, and on scientific research apparatus that generates high voltages.

What Types Of Metal Materials Do You Use To Make A Corona Ring?

What are the materials of corona rings? It depends on corona rings design and manufacturing process.

The custom aluminum corona rings are usually made from 6061 thin wall tubing or pipe that is formed and welded; with appropriate supporting brackets and other mounting standards.

In some conditions, the stainless steel materials will be used.

Aluminium Alloy:

Aluminum alloy is a popular metal material to use for corona rings production.

Because it is both cost effective and high weather resistance.

The soft hardness is easily processing and polishing.

Die casting rings materials are usually A380 and ZL101.

ZL101 die casting aluminum alloy can be strengthened by heat treatment, which has natural aging ability, high strength and good plasticity.

ZL101 die casting aluminum alloy has excellent casting properties, good fluidity, small linear shrinkage, low thermal cracking tendency and high air tightness. But it has a slight tendency to produce porosity and shrinkage.

This alloy has high corrosion resistance, good weldability and general machinability.

A380 type die casting aluminum alloy is the most common special aluminum alloy because it integrates the characteristics of easy casting, easy machining, and good heat conduction.

It has strong mobility, pressure bearing, and high temperature resistance.

Although the A380 type alloy has always been considered convenient for machining, it is slightly rough due to its higher silicon content.

It is widely used in various products, including chassis of electrical equipment, engine brackets, gearboxes, furniture, generators and hand tools, etc.

Of course, it is also the material of the aluminum die casting corona ring.

Stainless Steel:

Stainless steel is the kind of material which is not easy rust, acid resistance and corrosion resistance, so it is widely used in light industry and heavy industry.

Sometimes end users need some special corona rings made of stainless steel for outdoor applications.

Grade 201 reduces corona rings producing cost, increases mechanical strength and makes grade 201 work harden at a faster rate than grade 304 stainless steel material.

Grade 304 stainless steel material is a smart choice for your stainless steel corona rings project and longevity. It is cost-effective in comparison to other stainless steel materials.

Grade 304 material’s high quality and durability ensures that your product lasts a long time and the production of it is suitable for almost industry use.

Grade 316 stainless steel material, is a popular grade of stainless steel where superior corrosion resistance is of primary importance.

Grade 316 stainless steel corna ring is used for outdoor high voltage applications.

What Are Corona Rings And Shield Parts Surface Treatment?

Corona rings and shield parts surface treatment is one of the major factors every buyer should consider when purchasing them from China market.

The surface treatment is used to treat the exterior of corona rings and shields products by applying a thin complementary layer to their body surface.

There are many types of surface treatment processes for different applications.

- Polishing Surface Treatment: Usually the polishing silvery bright is the final main standard surface finish of corona rings and shields not only for the indoor high voltage laboratory centers but also for the outdoor transmission lines. The surface finish roughness is Ra3.2. The corona rings and shields production process is according to DIN ISO2768-MK general tolerances. Other manufacturing standard includes general tolerances for welded constructions, tolerances for lengths, angles, tolerances for shape and position, etc will be in accordance with EN ISO 13920-B-F.

- Insulating Varnish Painting Surface Treatment: For some outdoor applications, the coating insulating varnish corona ring and shield part will be used. To some extent this kind surface treatment could increase the corrosion resistance of aluminum corona rings and shielding components.

- Color Painting Surface Treatment: The color painting is the traditional process of applying a wet liquid paint to the corona ring and shield for finishing. Most rings and shields production processes will use a spray, pump, or pressurized vessel to deliver the wet paint evenly. This blue color painting corona rings and shields are often adopted in power transformer bushings design and manufacturing.

- Galvanized Surface Treatment: The galvanized process refers to a surface treatment technology that coats a layer of zinc on the surface of metals, alloys or other materials for aesthetics and rust prevention. The main method used is hot-dip galvanizing. This surface treatment is widely used in transmission line corona rings and insulator grading rings.

- Powder Coating Surface Treatment: Powder coating is a finishing process in which a coating is applied electrostatically to the ring’s or shield’s surface as a free-floating, dry powder before heat is used to finalize the coating. Powder coating can be finished as two methods: thermosets and thermoplastics. The powder can be made of many kinds of contents, such as polyester, polyurethane, polyester-epoxy, straight epoxy, and acrylics, etc. So the powder coating surface treatment can be used for aluminum corona rings and shields.

- Passivation Surface Treatment: It is a process used to improve the surface condition of aluminum rings and shields by dissolving the iron that is embedded in the surface by forming, machining, or other manufacturing steps. This is achieved by placing the aluminum corona rings and shields into an acid solution to dissolve the residual iron and to form a thin oxide layer on the surface of metal. It increased the corrosion resistance and maintains the dimensional integrity of close tolerance aluminum corona components.

- Oxidation Surface Treatment: This type of surface treatment is typically used for light metal, such as small aluminum corona rings and shielding parts. Anodization is a very common surface treatment that prevents corrosion on different corona rings and shielding parts.

What Are Corona Rings And Shielding Parts Packaging?

Usually, the wooden case and carton box are the two main types for corona ring and shield packaging.

Before placing the aluminum ring and shield into the wooden case or carton box, the product body is packaged with foamed paper firstly.

Wooden case and carton box four corners shall not be smaller than the outer diameter of the corona ring and shield.

Corona ring and shield’s surface four sides contacting with wooden case and carton box with foam mat protection.

In addition, clear labels are tagged on the outside of these packages for easy identification of these rings and shields measurements and quality information.

In addition, the big and strength pallet will be used for placing the cartons boxes. It will help packaging more stable during the transportation.

The fumigation wooden pallets and non-fumigation pallets are two kinds of wooden pallets types.

Because of the limit and customs requirements of various countries, so non-fumigation wooden pallets are widely used for carton boxes base support.

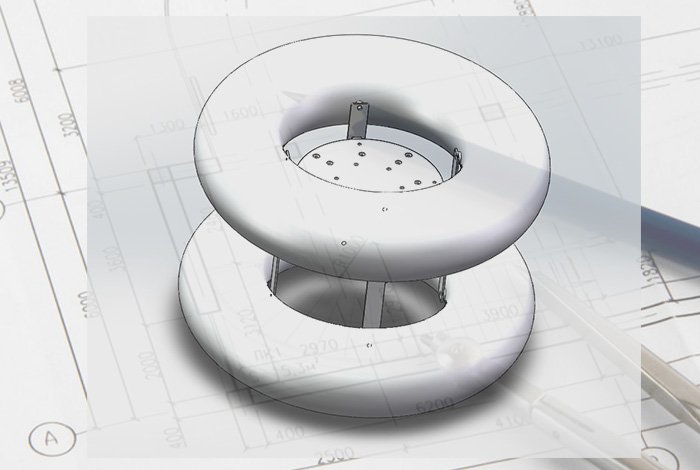

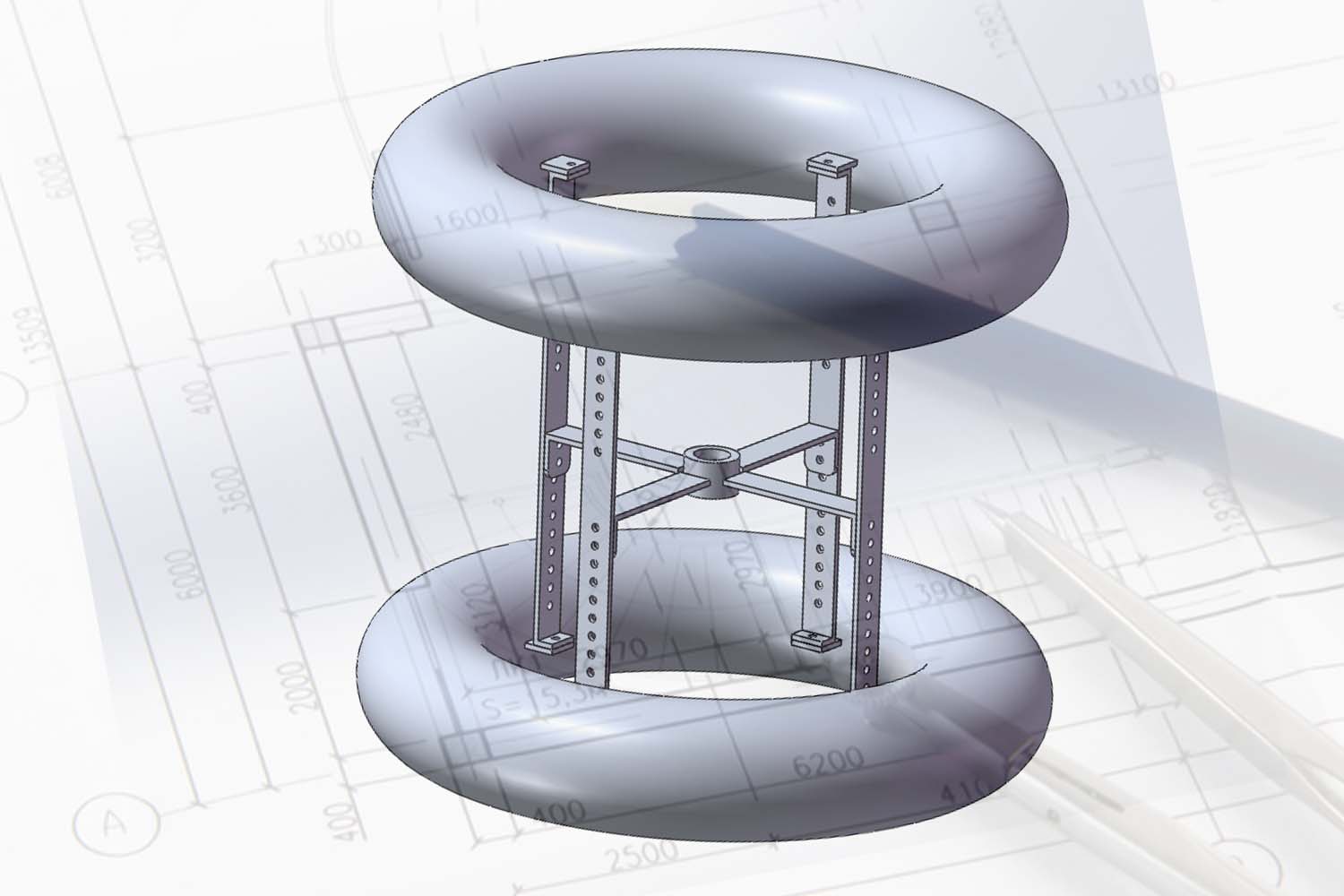

How About Corona Ring Design?

Are you thinking of designing your corona ring? If yes, then you have chosen the right platform as we are going to tell you all about the design of corona rings.

1.Choose The Right Material For High Voltage Corona Ring Design:

Aluminum alloy is the main material which have good weldability for corona ring design and production process. After the welding production, highv staff will set about doing polishing process. As you know, the soft aluminum material is easily for polishing for making sure the good corona effect. The ring are made of aluminum sheet and aluminum pipes. The bending tube production is easily for small rings. Because we only need the pipe bending machine to finish this step. The large rings production process is more difficult.

Grade 3A21, 6061, 6063 aluminum material are on highv stock. Before design the rings, we will confirm the right material with customers. More advantages of the common materials in corona shielding rings.

2.The Type Of Corona Ring Design:

Here two types of ring will be introduced. One is single ring without any brackets. Another one is known as corona ring set. It is also known as phase to earth ring set. The detailed design drawings will be offered by customers. Of course highv team could also help customer redesign new moulds and drawings.

3.Single Corona Ring VS Corona Ring Set Detailed Design Process:

Highv is professional at independent development and design. Our professional engineers team are skilled at AUTO CAD, PROE, SOLID WORKS and UG softwares. We are able to design, develop, produce and deliver rings according to customer detailed drawings, samples or just an idea. If the mould is our stock standard, the mould is free of charge. If it is customized one, the extra high voltage corona ring design drawing and fee will be needed.

How Do I Install My New Corona Ring For Power Transformer Bushing?

Installing a corona ring at the power transformer bushing can be difficult especially if it is your first time to do or you are green hand in corona rings operation.

As you know, the corona ring raw material is aluminum. Ring body must be handled carefully otherwise it could suffer external damages that can result in the failure of high voltage test.

1. Access to the bushing

2. Remove the old corona ring

3. Check the surface of the new corona ring for damage, defects or foreign materials.

4. Remove protective film from both sides of corona ring. Leave corona shield in place.

5. Apply contact grease to bushing body and/or contact surface of new corona ring.

6. Install new corona ring onto bushing body, tightening with provided bolts to manufacturer’s specification and torque wrench setting.

7.Reinstall bushing on transformer

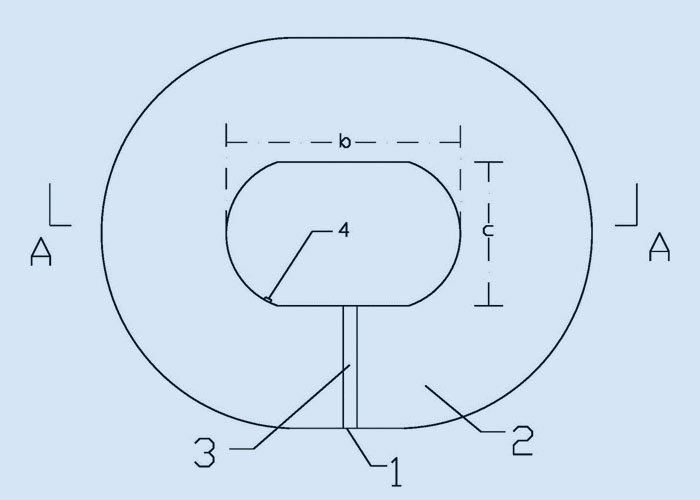

How Can I Choose The Right Size Of Aluminum Corona Rings?

Aluminum corona rings are widely used in high voltage testing systems such as power transformers and bushings.

The corona rings mainly play a role in the corona control. The surface of the aluminum corona ring is treated by anodizing, and it has excellent characteristics such as high strength, good wear resistance, etc.

But how to choose the right size of aluminum corona rings?

- The first parameter is the inner diameter ID of the corona ring.

- Second is the outer diameter OD of the corona rings.

- Third is the height H of the aluminum corona ring.

How To Get The Corona Ring Price From China Manufacturers?

In the current economic environment, more and more companies are looking for ways to reduce costs.

In all areas of the company, if you can find better options, you can reduce costs. The same applies to the purchase of goods. Many companies are hoping to find the best source of goods in China.

Although the cost is lower than the local production cost, some buyers worry that they will encounter quality issues when purchasing goods from Chinese factories.

In fact, if you work with professional suppliers in China, there is no need to worry about quality issues.

This guide will tell you how to get the best corona ring price from China manufacturers.

Step 1: Compare the corona ring price from different suppliers

As we all know that China has a huge manufacturing base, which means you can compare the prices of your product from many different suppliers, so you can choose the best price for you.

Step 2: Negotiate with manufacturers to get a better corona ring price

When you find a good supplier and want to buy their corona ring product, you can negotiate with them to get a better price.

Step 3: Get corona ring samples

After you find some potential suppliers, ask them for free corona rings samples. When you receive the samples, check their quality, and ask your customers or partners to check them as well. If everything is OK, then negotiate with the suppliers about the good price and other details.

If you are a buyer, the best way to choose the professional corona rings manufacturer is to compare and choose two or three suppliers then communicate with them firstly by mail, telephone or Skype. This is an important step because it can help you reduce the risk of being cheated. If you find them trustful, then you can visit their factory in China.

How To Find China Corona Ring And Corona Shielding Ring Manufacturer?

Every aluminum corona rings factory saying that they are the best has sort of becoming a cliché. You could find many corona rings manufacturers that say that their methods make them the best supplier there is.

Technically, we are discussing the exact same thing now.

We’re about to say that we are the masters when it comes to designing and manufacturing aluminum corona rings for many advanced companies. What’s more, we have some viable reasons that prove this fact and back up our claim.

So, without further ado, let’s get into a few reasons why our corona rings products and our HIGHV factory are the finest choices in the global markets.

Looking For Solutions In Corona Rings And Shields Industry

Our professional technical engineers team means we are available to you at any time! We can answer your questions about our products and solutions or offer comprehensive service for you.